From factory floors to solar fields: What you need to know about robotics adoption

The adoption of robotics across industries is no longer a futuristic concept but a present-day reality. Robotics and automation have long been the norm in certain industries, and more and more, businesses across previously less-automated industries are recognizing their transformative potential.

The progression of robotics technology into general industry is an inevitable shift that will empower people and businesses to be more productive, efficient, and competitive.

In this blog, you will learn:

- The current state of robotics adoption across industries.

- Top use cases for robotics technology adoption – the tasks you can expect robots to automate and the industries where you may see robots next.

- How one robot is paving the way for billions of solar panels to be installed to scale the solar industry.

The rise of robotics adoption: There are more robots in operation than you might realize.

When visualizing a robot, one may think of a futuristic humanoid robot, like C-3PO from Star Wars. While humanoid robots are on the rise, the reality is that most robots are of the industrial variety. This could look like a robotic arm lifting heavy parts in an automotive factory, a small needle-like robot assembling electronic computer pieces, or a remote-controlled robot that detoxes chemical laboratories.

Whatever their shape or form, most robots are used to:

- Improve efficiency through streamlined processes.

- Improve quality in refined tasks.

- Enhance worker safety and productivity.

Now, robotics have moved beyond traditional industry applications and indoor settings – like automotive and electronics – to new industries and outdoor settings. Now, 50% of all new industrial robot installations are coming from general industry – which includes construction, agriculture, and all other industries.

The growth is substantial.

- ~4 million industrial robots in operation worldwide as of 2022.

- By 2030, 80% of humans will engage with smart robots daily, up from less than 10% today.

- ~1,000 service robot suppliers worldwide, showing the wide spectrum of applications.

The adoption of collaborative robots – robots that work alongside human operators – now hold a more than 10% share of the industrial robotics market. The use of autonomous robots is also increasing across industries.

Use cases and trends driving robotics adoption: Where you can expect to see robots next

Robotics are not a new phenomenon for some industries. Industries in controlled environments that involve a high amount of repetitive manual tasks or safety challenges have successfully incorporated automation into their processes to enhance productivity, streamline processes, and reduce errors. World Economic Forum’s (WEF) Future of Jobs Report 2023 predicts that the following industries are the most likely adopters of automation technology in the near future:

- Electronics

- Energy Technology and Utilities

- Consumer Goods

While few occupations are fully automatable, 60% of all occupations have at least 30% technically automatable activities.

Activities with the highest automation potential.

- Predictable physical activities: 81%

- Processing data: 69%

- Collecting data: 64%

By 2027, approximately 36% of tasks are expected to be automated in physical labor.

Embracing the inevitable and addressing concerns: What robotics adoption means for employment and productivity.

One of the primary concerns surrounding robotics technology adoption is the potential impact on employment. However, studies show that robots complement and augment human activity rather than replace it.

- Less than 10% of jobs are fully automatable, meaning that robots substitute certain repetitive or mundane tasks within jobs rather than eliminating the jobs themselves.

- Automation can create a global productivity growth of 0.8% to 1.4% annually, enabling companies to maintain or enhance their market positions.

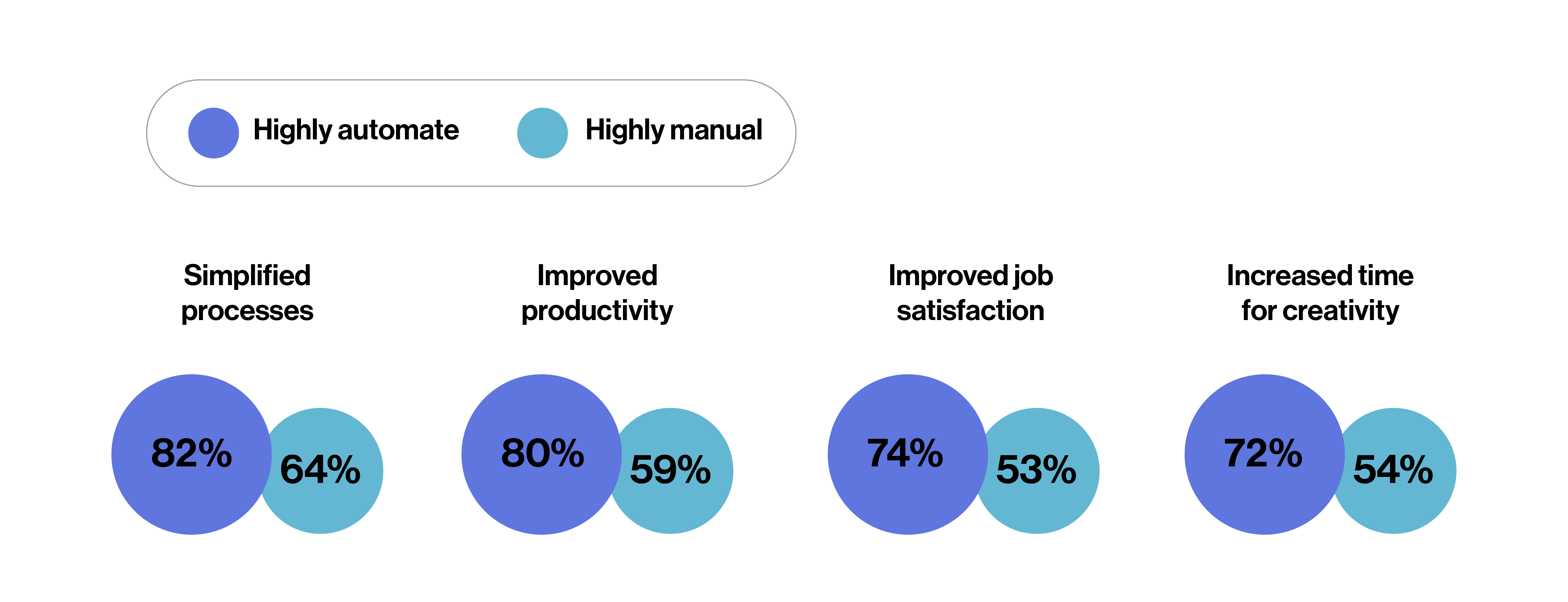

By automating repetitive, menial, and hazardous tasks, humans will have more opportunities for higher-skilled, higher-quality, and higher-paid activities. This ultimately improves wellbeing, with 74% of employees in the most automated companies citing improved job satisfaction in one study.

Source: Workflow by service now, “Productivity depends on people: Automating routine tasks yields happier, more productive employees.” 2019. Survey of 6,000 people.

The shift towards robotics and automation is not just a trend but an essential evolution in business practices. Businesses that embrace this change will find themselves at the forefront of innovation, capable of navigating the complexities of modern markets and securing a competitive edge.

Robotics in the solar industry: How automation can accelerate growth and meet workforce demand.

Demand for electricity is expected to double by 2050. At the same time, demand for green energy solutions continues to intensify alongside pressure to deliver on climate objectives. This surge necessitates the rapid deployment and scaling of cost-competitive renewable energy.

By 2035, annual solar additions are expected to increase 3X, and the workforce will have to nearly double. However, job growth is expected to outpace supply, and solar must find a cost-effective way to build more efficiently to keep up with project pipeline. Robotics and automation can drive efficiency, enhance safety, and meet the growing demand for renewable energy solutions.

Robotics automation can accelerate solar deployment

- Robotics offer a solution to these challenges: Despite being relatively new, the solar industry has matured quickly and is poised to streamline construction steps. Repetitive, predictable, and injury-prone physical activities – such as installing a solar module – have the highest potential for automation. The introduction of robotics into the solar installation process has the potential to:

- Increase installation speed and efficiency: With the ability to work for extended periods of time, and increase employee-reported productivity, automation can significantly speed up the installation process while ensuring consistent quality.

- Enhance safety: By taking over physically demanding tasks, automation reduces the risk of injury and improves working conditions for team members. This is particularly important in solar farm construction, where heavy lifting of increasingly large solar panels and exposure to harsh weather are common.

- Reduce costs: Automation can lead to cost savings, such as by minimizing errors during installation and decreasing injury risk. These savings can be passed on to customers, making solar energy more affordable and competitive.

- Create more inclusive jobs: By automating the physically demanding tasks of solar installation, people previously in these roles can transition to less injury-prone and more accessible roles, including robot operation and supervision.

Maximo: How the newest innovation in solar is using AI-enabled robotics to deploy solar panels in ½ the time and ½ the cost.

As the world's first AI-enabled solar robot, Maximo is set to transform the way solar modules are installed, making the process faster, safer, and more cost-effective. Maximo is the only robot that carries out the full end-to-end automation for the mechanical installation of solar modules.

With its advanced artificial intelligence-enabled design, Maximo automates the heavy lifting and accelerates installation processes, ensuring projects meet tight project deadlines, improve safety, combat rising costs, and deliver more megawatts in less time. Maximo represents the future of solar installation as a partner to construction teams to keep them safe while helping to build the gigawatts of solar the world needs to combat climate change.

Conclusion

Robotics adoption is pivotal in ensuring that the solar industry is able to rapidly scale to meet the significant demand growth, create high quality jobs, and ensure the transition to a clean energy future. By leveraging AI, introducing mobile robots into outdoor environments, and building advanced, green-powered solutions, the solar industry can meet the growing demand for green energy and ensure the transition to a clean energy future is both sustainable and inclusive.